In today’s fast-paced, globalized world, the ability to preserve food, pharmaceuticals, and other temperature-sensitive goods is critical. Behind the scenes of restaurants, supermarkets, hospitals, and warehouses lies an unsung hero of modern infrastructure—the modular coldroom. But how did we get here? The story of modular coldrooms is one of ingenuity, industrial progress, and the growing demand for flexibility in cold storage.

Before Modular Coldrooms: Early Refrigeration

Cold storage is far from a new idea. Before refrigeration technology, civilizations used natural methods like ice houses, cellars, and snow storage to preserve perishables. By the 1800s, mechanical refrigeration emerged, revolutionizing industries. Early coldrooms were built into buildings, made of thick brick and insulated with sawdust or cork. These systems were large, immovable, and expensive.

The Birth of Modular Coldrooms: Mid-20th Century

As technology advanced in the mid-20th century, the food industry grew rapidly, and global trade began expanding. There was a pressing need for more flexible, scalable, and cost-effective cold storage solutions.

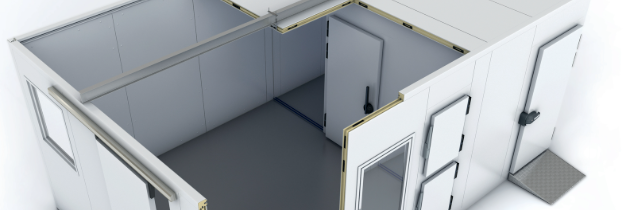

This led to the concept of modular coldrooms—rooms constructed from prefabricated insulated panels, often using polyurethane or polystyrene foam sandwiched between metal skins. These panels could be assembled and disassembled quickly, allowing for rapid deployment and easy transport. The modular design offered scalability, so businesses could expand their cold storage incrementally without overhauling infrastructure.

Standardization and Commercial Growth: 1970s–1990s

Throughout the 1970s and 1980s, modular coldrooms became increasingly common in hospitality, retail, and pharmaceuticals. Innovations in panel interlocking systems, door sealing technologies, and refrigeration units made them more reliable and energy efficient.

The foodservice boom of the 1980s, especially the rise of fast-food chains and large supermarkets, drove demand for coldrooms that could be installed quickly and adapted to various floor plans. Modular units could be configured to exact specifications, from compact back-of-house coolers to large industrial walk-ins.

Modern Advances: 2000s–Present

The 21st century brought smarter materials and digital innovation. Today’s modular coldrooms often include:

IoT monitoring systems for real-time temperature and humidity tracking

Eco-friendly refrigerants and energy-efficient compressors

Rapid-assembly systems for temporary or mobile installations (e.g., disaster relief, pop-up medical facilities)

Compliance with global standards for hygiene, safety, and sustainability

Additionally, industries like biotechnology, floriculture, and e-commerce have increased the demand for specialized cold storage—from ultra-low freezers for vaccines to temperature-controlled logistics hubs.

Why Modern Coldrooms Matters Today

What began as a way to simplify construction has become a critical design philosophy. Modularity means businesses can respond quickly to changing demands—whether it’s a surge in online grocery delivery, a seasonal harvest, or a public health emergency.

The modular coldroom is more than just a storage box—it’s a testament to how thoughtful engineering can meet human needs for safety, convenience, and efficiency.

Summary

The history of modular coldrooms reflects a broader trend in industrial innovation: adaptability. From humble beginnings to high-tech, energy-efficient solutions, these systems continue to evolve to meet the cold chain challenges of tomorrow.

Whether you’re in food service, healthcare, or logistics, the next time you step into a coldroom, remember—you’re standing in a piece of modern history.