Polyurethane is a common plastic that appears in many forms and applications. First developed in 1940, it was initially used in World War II aircraft. Today, it plays a vital role in everything from surgical tools and car parts to children’s toys and furniture. Thanks to its adaptability, polyurethane continues to evolve with modern technologies.

How Is It Made?

Chemically speaking, polyurethane is a polymer—a large molecule made up of repeating smaller units called monomers. It is formed by reacting two key ingredients: diisocyanate and a diol. This chemical process creates a flexible base material that can be tailored for specific uses.

The Benefits

Polyurethane is known for its flexibility, resilience, and durability. It can be stretched, scratched, or compressed and still retain its form. Often used as a substitute for materials like rubber, wood, metal, or cotton, it has countless applications across industries.

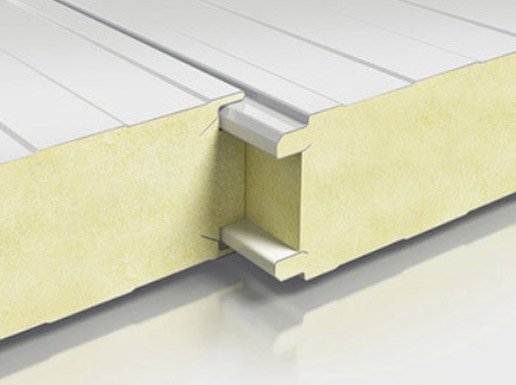

Thermoplastics

Polyurethane can also take the form of thermoplastics—rigid, smooth materials that resemble plastic, fibreglass, or metal. These surfaces are water-resistant, making them ideal for insulation and protective applications. They also offer various heat-resistant and insulating properties.

Everyday Uses

Polyurethane is found in a wide variety of products, including:

Furniture cushioning

Mattresses

Car components

Industrial machinery

Surgical instruments

Paints and wood coatings

Rollers and tyres

Shoe soles and sportswear

Toys

Building and sound insulation

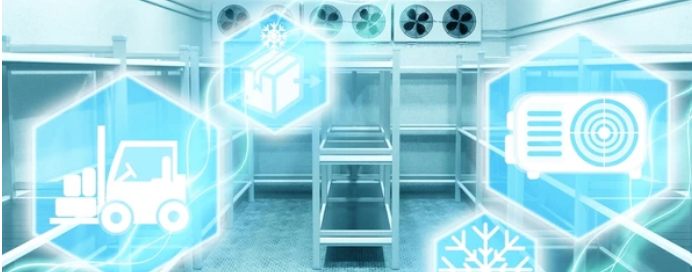

Fridge and freezer insulation

About Us

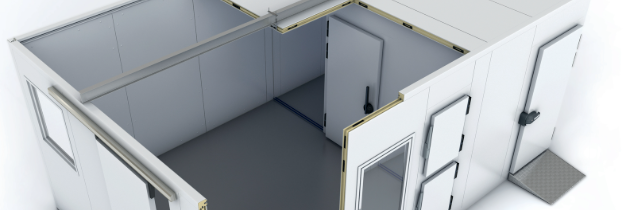

At ColdSafe, we design and manufacture high-performance polyurethane-insulated panels and doors tailored for temperature-controlled environments. As specialists in coldstore solutions, we can custom-build walk-in or drive-in cold rooms to fit your space and requirements.

Contact us today on info@coldsafe.co.uk if you have any questions or would like a personalised quotation.