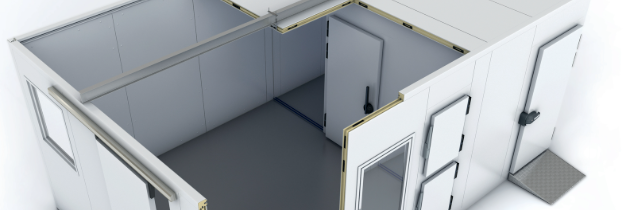

Designing a modular cold room layout is more than just assembling insulated panels—it’s about creating a functional, energy-efficient space that supports your operations and preserves the integrity of temperature-sensitive products. Whether you’re in the food industry, pharmaceuticals, floriculture, or logistics, your layout directly impacts your energy consumption, workflow, and long-term cost savings.

At Coldsafe, we understand how critical the right design is. In this guide, we walk you through the essential steps to planning an effective cold room layout that is scalable, compliant, and built to perform.

A well-planned layout enhances airflow, optimizes temperature distribution, and allows for efficient movement of products and personnel. It also ensures maximum use of space, reduces strain on refrigeration systems, and makes routine maintenance easier. Starting with a solid layout plan helps avoid future inefficiencies and costly retrofits.

Step-by-Step Guide to an Efficient Modular Cold Room Layout

The first and most important step is understanding your product requirements. Consider what type of goods you’ll be storing, their ideal temperature range, and any special humidity or ventilation needs. For instance, frozen foods may require temperatures as low as -18°C, while pharmaceuticals typically need a stable range between +2°C and +8°C. Turnover rate, product volume, and storage duration will also influence how your cold room is structured.

Next, calculate the cooling load. This step is crucial to ensure that your refrigeration system is neither underpowered nor excessively large. At Coldsafe, we use advanced thermal load calculation tools to assess variables such as product load (the heat the stored items release), heat gain from external walls and doors, internal lighting, personnel activity, and air infiltration from door openings. An accurate cooling load estimate leads to better energy efficiency and system performance.

Selecting the right location for your cold room also plays a vital role. Ideally, it should be installed in an area with minimal exposure to direct sunlight, proper drainage, and good ventilation. Accessibility is another consideration—your layout should allow for smooth delivery and dispatch of goods, while also meeting local safety and building regulations. Our Coldsafe experts offer on-site surveys to evaluate installation suitability and optimize cold room placement.

Once the external factors are addressed, it’s time to focus on the internal layout. Efficient airflow is key, so avoid blocking evaporator units with product racks. Create dedicated zones to store products based on category, turnover rate, or expiry dates. Aisle width should allow for easy movement of trolleys or forklifts without compromising air circulation. Importantly, leave sufficient space for equipment servicing and cleaning. Coldsafe’s modular systems can be tailored with custom racking and internal organization features to support your unique workflow.

The type and placement of cold room doors can significantly impact energy efficiency. Smaller cold rooms often use hinged doors, while larger setups benefit from space-saving sliding doors. In high-traffic or hygiene-critical environments, automatic doors are a preferred choice. To minimize heat exchange, doors should be positioned strategically—away from direct airflow paths and near loading zones when possible.

Future flexibility is another vital aspect. Modular systems offer the advantage of easy expansion. Whether you’re increasing storage space or adapting to seasonal changes, Coldsafe provides panel-based systems that can be reconfigured, extended, or even relocated with minimal disruption.

Modern cold rooms also benefit greatly from smart control systems. Coldsafe integrates digital temperature and humidity controllers that offer real-time monitoring, remote alerts, and data logging. These systems not only improve food or pharmaceutical safety but also help reduce energy usage through precise environmental control.

Pro Tips from Coldsafe for Maximum Efficiency

For additional thermal control, consider using high-speed or self-closing doors and PVC strip curtains, especially in busy areas. Internal LED lighting should be used to reduce heat output, and cold rooms storing critical products should include a backup power supply to avoid spoilage during power failures. These small design choices can significantly enhance efficiency and reliability.

Contact Coldsafe for a tailored Cold Room Design

At Coldsafe, we specialize in designing and installing bespoke modular cold room systems for businesses across industries. Our solutions are space-efficient, energy-smart, and fully compliant with industry standards like HACCP and GMP. We provide a complete turnkey service—from consultation and layout design to full installation and support—ensuring your cold room delivers peak performance from day one.

Whether you’re building a food processing facility, a pharmaceutical warehouse, or a retail cold store, Coldsafe’s modular solutions are designed to meet your current and future needs with ease.

Summary

Designing an efficient modular cold room layout is a smart business decision. It enhances product safety, lowers energy bills, and streamlines daily operations. With the right guidance and a trusted partner like Coldsafe, you can design a cold storage solution that works seamlessly for your business today—and scales with you tomorrow.

Ready to optimize your cold room layout? Contact Coldsafe today for a personalized consultation and site assessment.