In today’s temperature-sensitive industries, from food and beverage to pharmaceuticals and logistics, maintaining precise environmental conditions is critical. At the core of many cold storage facilities are high-quality insulated panels—engineered systems that provide superior thermal insulation, structural integrity, and hygienic surfaces. These panels aren’t just construction materials; they’re a strategic investment in quality, efficiency, and compliance.

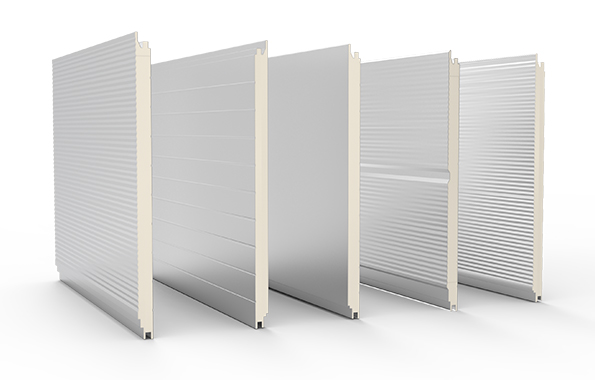

What Are Insulated Panels and How Do They Work?

Insulated panels are prefabricated components made up of two durable exterior layers—usually steel or aluminum—surrounding a core of thermal insulation. Common insulation materials include polyurethane foam (PU), polyisocyanurate (PIR), and expanded polystyrene (EPS), each offering varying levels of performance based on application needs.

These panels are designed to create highly controlled environments by minimizing heat transfer, ensuring consistent internal temperatures regardless of external conditions.

Key Qualities of Modern Insulated Panels

One of the most important characteristics of high-quality insulated panels is their excellent thermal insulation, which helps maintain stable conditions in cold storage environments. This consistency not only ensures product integrity but also significantly reduces energy consumption and operational costs.

Durability is another major advantage. These panels are resistant to corrosion, moisture, and physical impact, making them ideal for both indoor and outdoor use. Many are customizable in size and thickness, allowing businesses to tailor solutions to specific temperature ranges or spatial constraints.

Hygiene is critical in industries such as food processing and pharmaceuticals, and the smooth, non-porous surfaces of these panels make them easy to clean and maintain. As a result, they help support strict cleanliness standards required by regulatory bodies.

Benefits That Go Beyond Insulation

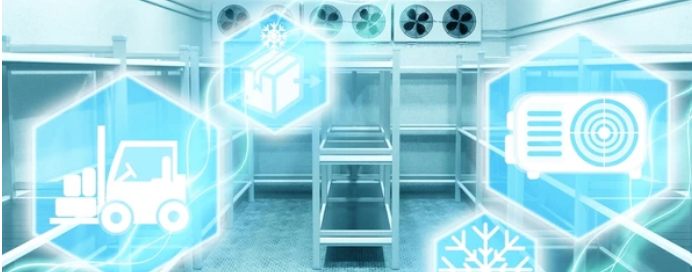

The use of insulated panels in cold storage offers a wide array of benefits. Energy efficiency is a major one—better insulation means less energy is required to maintain low temperatures, translating into long-term cost savings. These panels also allow for precise temperature control, which is essential for preserving perishable goods and maintaining compliance in regulated industries.

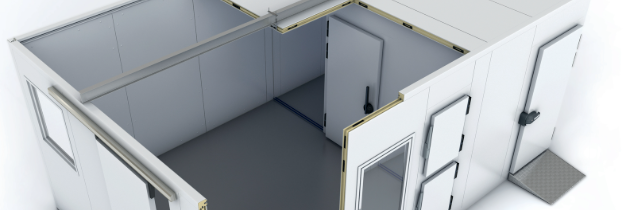

Installation is fast and straightforward, thanks to the panels lightweight, prefabricated nature. This can significantly reduce construction time and help businesses launch operations sooner. Many manufacturers now also offer sustainable panel options made with recyclable materials and eco-friendly insulation cores, aligning with green building initiatives.

Where Are Insulated Panels Are Used?

Insulated panels are a staple in the food and beverage industry, where they help keep items like dairy, meat, seafood, and produce fresh. In the pharmaceutical sector, they play a vital role in maintaining the cold chain for medicines and vaccines.

Logistics companies depend on insulated panels to build cold storage hubs and transport facilities that preserve product quality throughout distribution. In agriculture, farmers use them to store crops and flowers post-harvest, reducing spoilage. Even supermarkets rely on these panels to construct walk-in freezers and display units that meet both functional and aesthetic needs.

Types of Insulated Panels for Cold Storage

The most commonly used panels are PUF panels, which provide excellent thermal efficiency and are widely used in both chillers and freezers. PIR panels are a step up in fire resistance, making them ideal for environments with higher safety requirements. For cost-effective solutions, EPS panels offer reliable insulation for moderate temperatures. In cutting-edge applications, vacuum insulated panels (VIPs) are gaining popularity for their ultra-thin, highly efficient insulation, particularly where space and energy conservation are top priorities.

Choosing the Right Insulated Panel

Selecting the ideal panel depends on several factors. Start by identifying your product’s temperature requirements—this will guide your decision on insulation thickness and material type. Panels with higher R-values offer better insulation and energy efficiency, while durability should be considered based on exposure to moisture and potential wear and tear.

It’s also important to verify that the panels meet industry standards, especially in regulated sectors like food storage or pharmaceuticals. Finally, consider installation and maintenance requirements; the easier they are to install and care for, the more cost-effective your solution will be in the long run.

Maintaining Panel Performance

To keep your insulated panels functioning at their best, conduct regular inspections for signs of damage such as cracks, dents, or moisture buildup. Surfaces should be cleaned using non-abrasive agents to maintain hygiene, and all seals and joints should be checked to prevent temperature leaks.

The refrigeration system that supports your insulated structure should also be serviced regularly. If your existing panels no longer meet performance or efficiency expectations, upgrading to newer models can restore reliability and reduce operating costs.

The Future: Innovation in Insulated Panel Technology

As cold storage technology evolves, so do insulated panels. Today’s advanced systems are integrating Internet of Things (IoT) capabilities, enabling remote temperature monitoring and control via mobile or web interfaces.

Manufacturers are also focusing on sustainability, with new panels made from recyclable or biodegradable materials. Fire safety is being enhanced through materials that provide greater flame resistance and emit less smoke. Additionally, smart energy management systems are being built in to optimize power consumption and further reduce environmental impact.

Final Thoughts

High-performance insulated panels are a critical asset for any operation that depends on precise temperature control. They combine superior insulation, durability, hygiene, and energy efficiency—qualities that make them essential in cold storage environments across a range of industries.

By investing in the right panels and maintaining them properly, businesses can ensure product safety, meet regulatory standards, reduce operational costs, and support sustainability goals. As the technology behind insulated panels continues to advance, the possibilities for efficient and intelligent cold storage are expanding rapidly.

If you are considering using a modular cold room or simply would like more information, please do not hesitate to contact us for support on info@coldsafe.co.uk