Modular coldrooms are a crucial part of the cold storage industry, offering scalable, customizable, and energy-efficient solutions for businesses that rely on temperature control. Whether you’re in food processing, pharmaceuticals, hospitality, or logistics, understanding the components that make up a modular coldroom helps you choose the right solution for your needs.

At ColdSafe, we believe in educating our clients to make informed decisions. In this blog, we’ll break down the key components that form the backbone of a modular coldroom.

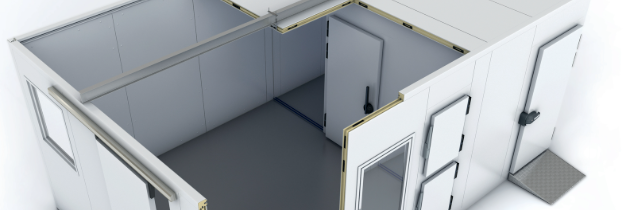

🔩 1. Insulated Panels (Walls, Floors, and Ceilings)

The insulated panels are the building blocks of a modular coldroom. Typically made from polyurethane (PU) or polyisocyanurate (PIR) foam sandwiched between steel sheets, these panels provide:

Thermal insulation to maintain internal temperature.

Structural integrity for easy assembly and reconfiguration.

Hygienic surfaces that comply with food and pharmaceutical safety standards.

At ColdSafe, our panels are precision-engineered for high thermal resistance (R-values), helping you save on energy costs.

❄️ 2. Refrigeration System

No coldroom can function without an efficient refrigeration unit. This system includes:

Condensing Unit (compressor + condenser)

Evaporator (cooling coil and fan)

Temperature Controller

Refrigeration systems can be designed for chillers (0°C to +10°C) or freezers (-18°C and below). ColdSafe customizes every setup based on your industry and volume requirements to ensure consistent performance.

🚪 3. Coldroom Doors

The type and quality of the coldroom door significantly affect performance. Options include:

Hinged Doors – Ideal for smaller units and low-traffic use.

Sliding Doors – Perfect for large or high-traffic environments.

Automatic or Manual Options

All ColdSafe doors are built with thermal breaks and tight seals to prevent cold air leakage and improve energy efficiency.

🧭 4. Control Systems & Monitoring

Modern modular coldrooms often include digital control panels for:

Temperature settings

Defrost cycles

Alarm systems for malfunctions or door openings

ColdSafe offers smart coldroom monitoring with remote access, allowing you to keep track of conditions 24/7, even when you’re off-site.

🧼 5. Flooring Systems

Flooring depends on the use case:

Insulated floors for freezer rooms or where ground heat ingress is an issue.

Non-slip, food-safe flooring for hygienic requirements.

ColdSafe coldroom floors are built to support heavy loads, resist bacterial growth, and stand up to daily wear and tear.

💨 6. Air Curtains & Strip Curtains (Optional)

To further reduce thermal loss when doors are open, some setups include:

PVC strip curtains

Air curtains or blowers

These accessories are particularly useful in busy facilities to maintain internal temperature.

🧱 7. Modular Framework & Assembly System

Modular coldrooms are designed for easy expansion, relocation, or disassembly. The tongue-and-groove panel connections and cam-lock systems used by ColdSafe make installation quick and secure with minimal disruption.

🧊 Why Choose ColdSafe Modular Coldrooms?

At ColdSafe, we don’t just sell coldrooms—we deliver peace of mind. Our units are:

✅ Custom-built for your industry

✅ Easy to install and expand

✅ Designed for energy efficiency

✅ Backed by expert support and warranty

📞 Ready to Build or Upgrade Your Coldroom?

Whether you need a small walk-in chiller or a large-scale warehouse freezer, ColdSafe has the perfect modular coldroom solution tailored to your needs.

👉 Contact ColdSafe today for a free consultation at info@coldsafe.co.uk.