In industries where temperature control is critical—such as food service, pharmaceuticals, and logistics—modular cold rooms have become the go-to solution for reliable and scalable refrigeration. At ColdSafe, we specialize in providing state-of-the-art modular cold storage systems that adapt to your needs.

But how exactly do these systems work? In this blog, we break down the inner workings of modular cold rooms and explain what makes them such a smart investment.

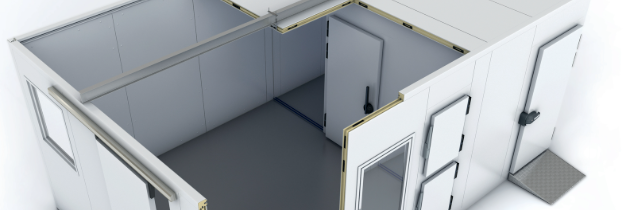

What Is a Modular Cold Room?

A modular cold room is a walk-in refrigeration unit built from prefabricated, interlocking panels that can be easily assembled, disassembled, and customized. Unlike traditional built-in cold storage, modular cold rooms offer flexibility in size, layout, and application—making them ideal for businesses that need scalable and relocatable solutions.

Key Components and How They Work

Let’s take a closer look at the major elements of a modular cold room:

🧊 1. Insulated Panels

The structure of a modular cold room is made from insulated sandwich panels, typically with a polyurethane (PU) or polyisocyanurate (PIR) core and steel or aluminum exterior. These panels lock together tightly to create an airtight and thermally efficient environment.

Purpose: Maintain internal temperature and prevent external heat from entering.

Benefit: Reduces energy consumption and keeps stored products safe.

❄️ 2. Refrigeration Unit

This is the heart of your cold room. It includes:

Compressor: Compresses refrigerant gas to high pressure and temperature.

Condenser: Releases heat from the compressed refrigerant.

Expansion Valve: Reduces the pressure of the refrigerant before it enters the evaporator.

Evaporator Coil (Inside the Room): Absorbs heat from the air inside, cooling the interior.

The refrigeration unit can be mounted on the wall (monoblock) or split into indoor and outdoor components, depending on space and cooling requirements.

🔄 3. Temperature Control System

Modern modular cold rooms, like those designed by ColdSafe, come with digital thermostats and temperature monitoring systems. These allow precise control over temperature and humidity levels, and often include alarm systems and remote monitoring for added security.

🚪 4. Doors and Flooring

Doors: Typically hinged or sliding, with heavy-duty seals to ensure no cold air escapes.

Flooring: Insulated floors or anti-slip steel floors are often included, depending on whether the unit is installed indoors or outdoors.

🧠 5. Smart Features

Some advanced models include IoT connectivity for remote access, automatic defrosting, energy consumption reports, and more. At ColdSafe, we offer optional smart upgrades that give you complete control over your cold storage—right from your smartphone or computer.

Why Modular Cold Rooms Are So Effective

Flexible & Scalable: Easily increase storage capacity as your business grows.

Quick Installation: Prefabricated panels allow for fast setup, minimizing downtime.

Relocatable: Move the unit to another site when needed.

Cost-Efficient: Lower energy bills thanks to advanced insulation and efficient design.

Who Uses Modular Cold Rooms?

Restaurants & Catering Businesses

Hospitals & Pharmacies

Food Processors

Agricultural Facilities

Supermarkets & Retail Chains

Anywhere that consistent, controlled cooling is vital—you’ll find ColdSafe solutions hard at work.

Summary

Understanding how modular cold rooms work helps you make informed decisions about cold storage for your business. With customizable sizes, smart controls, and reliable temperature performance, they offer a modern solution to a timeless challenge: keeping things cool, safe, and efficient.

At ColdSafe, we design and install modular cold rooms tailored to your exact needs—whether you’re storing perishable food, life-saving medicine, or temperature-sensitive materials.

📞 Want to learn more or get a quote?

Contact ColdSafe today on 01905 672905 and let us build the perfect cold storage solution for your business.